Specification & Configurations

Fabox is a next-generation modular structure designed for the world of events, exhibitions, retail activations, and temporary architecture. Built for both indoor and outdoor environments, each Fabox unit offers a premium, all-season space that can be configured, stacked, and branded to meet almost any creative or functional brief.

Structure & Build

Built to perform with precision engineering and premium materials.

- What materials and finishes are used in Fabox construction?

- Fabox units are constructed from high-grade S355 structural steel using SHS, UB, and UC sections joined with grade 8.8 bolts. The walls and roof use insulated composite panels or double-glazed systems depending on the design, fully sealed for weather resistance. External steelwork is powder-coated or painted, while interiors can include vinyl, timber, or carpet flooring with finished wall panels and integrated lighting, resulting in a strong, premium, and weatherproof structure suitable for repeated outdoor use.

- What is the structural frame made from?

- The Fabox frame is a welded and bolted steel structure made from S355 grade steel, with 8.8-grade high-strength bolts for assembly. It uses SHS 150×150×5 mm posts, UB 254×146×31 top beams, and UC 152×152×23 bottom beams for rigidity, with steel purlins supporting the roof and floor. All connections are engineered to Eurocode 3 standards, primed, and coated for corrosion resistance to ensure strength, safety, and long service life.

- What insulation and weatherproofing features are included?

- Fabox incorporates insulated composite wall and roof panels with rigid PIR cores and sealed joints for complete water and air tightness. The structure includes EPDM gaskets, silicone seals, and thermally broken glazing to maintain comfortable internal temperatures. All external elements are corrosion-protected and weatherproof, enabling year-round use in harsh environments.

- What are the overall and internal dimensions (L x W x H)?

- Overall 5670 mm × 2880 mm × 2880 mm (H). Each Fabox unit measures 5.36 m in length, 2.68 m in width, and 2.68 m in height externally, providing a usable internal area of roughly 5.2 × 2.5 × 2.4 m. The compact footprint allows easy transport and stacking while maintaining generous internal space for fit-outs.

- How much does each unit weigh?

- A single Fabox unit weighs around 5.8 tonnes, including the steel frame, flooring, and wall systems. This weight ensures structural stability and safe stacking while remaining efficient to transport and install.

- What is the modular grid size or base footprint?

- The modular grid is based on a standard 5.36 m × 2.68 m footprint, allowing seamless connection of multiple units side by side or vertically stacked to create larger structures or multi-storey configurations.

- Are the modules limited to rectangular layouts, or can curves be integrated?

- The main steel frame is rectilinear, but curved facades or decorative cladding can be added externally to achieve unique architectural forms without changing the core structure.

- What are the options for wall systems (glass, insulated, solid, or mixed)?

- Fabox wall systems include solid insulated panels, full-height glazing, or mixed designs with optional branding cladding. These interchangeable panels allow flexibility in thermal performance and visual style for each project.

- Does it include a ceiling system?

- Yes, Fabox is supplied with either an insulated ceiling or a suspended system to conceal lighting and services, both fully modular and reconfigurable.

- What are the available roof styles (flat, terrace, tensed, etc.)?

- Roof options include standard flat insulated roofs, load-bearing terrace decks with balustrades, or stretched membrane canopies for visual and functional variety.

- What engineering standards apply?

- Designed and certified to international engineering standards including Eurocodes (EN 1990–1999) and BS EN 1090 for steel/aluminium structures, with compliance to TDS guidance and CDM 2015 in the UK. For Australia, compliant with NCC/BCA, AS/NZS 1170 (wind/snow), AS 4100/1664 (steel/aluminium), and AS 1530 (fire). Electrical systems meet BS 7671 / AS 3000. Full engineer-stamped drawings and calculations provided for permitting.

Configurations & Scalability

Combine, expand, and elevate — your space, your way.

- Can Fabox units be joined or stacked? How high?

- Fabox modules can be joined in any direction and safely stacked up to eight levels high. All connections are verified through engineering calculations, allowing flexible layouts and multi-level designs.

- Can it be configured in different footprints or shapes?

- Yes, the modular grid allows Fabox units to form linear, L-shaped, U-shaped, or courtyard layouts, offering creative freedom without compromising structural integrity.

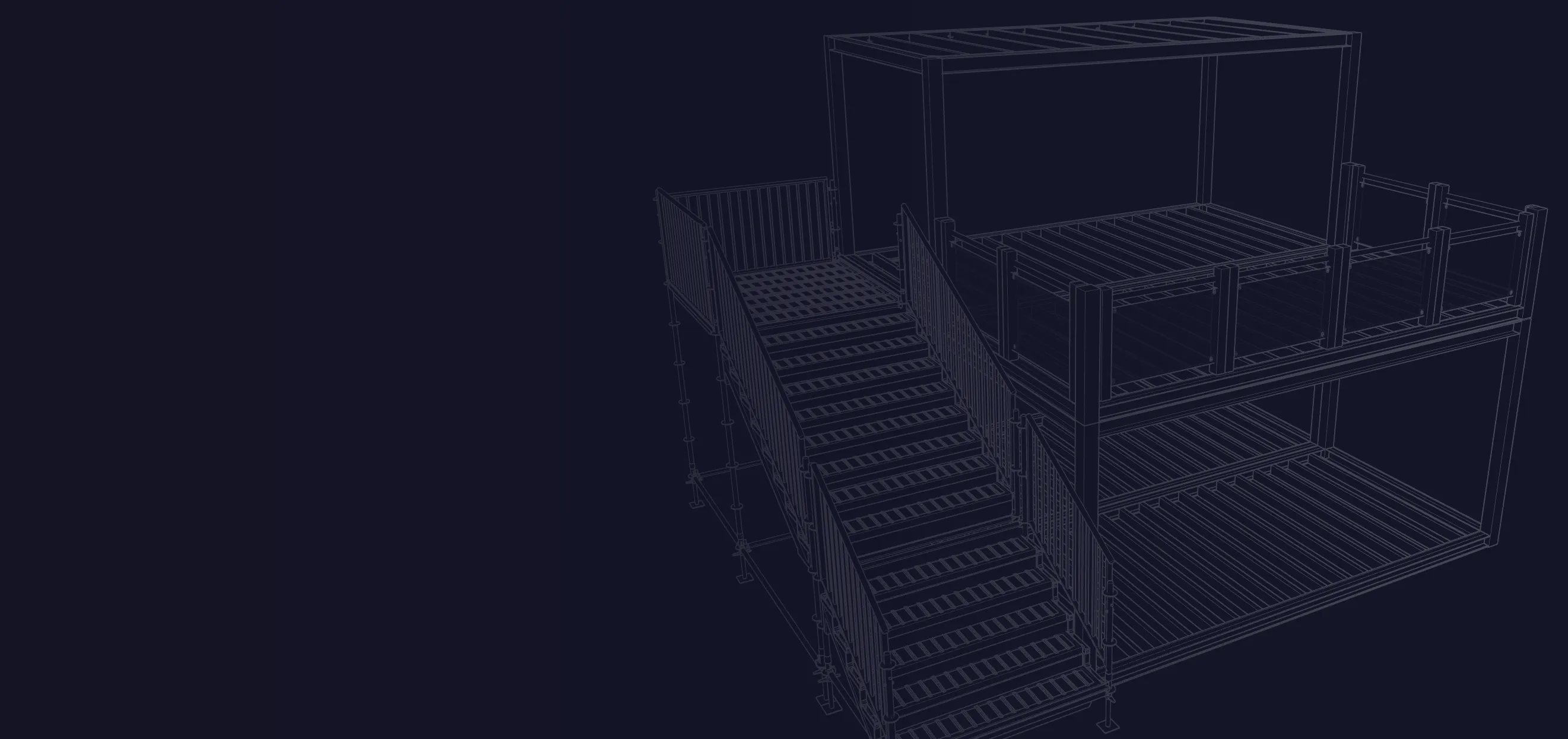

- What types of stairs or access systems are available (straight, spiral, internal/external)?

- A range of steel stair options is available, including straight, spiral, internal, and external access types, all modular and compliant with UK and Eurocode safety standards.

- Can terraces, balconies, or roof decks be added?

- Yes, Fabox can support terraces and balconies engineered to Eurocode loading standards, creating functional outdoor areas ideal for hospitality or brand showcases.

- Can units be joined to create large open spans or enclosed areas?

- Yes, adjacent walls can be removed between connected units to create wide, open interiors or enclosed halls while maintaining structural stability.

- Are there limitations on the number of units combined?

- Fabox can be joined endlessly in plan; vertical height is limited by structural engineering, typically up to eight storeys depending on layout and loading.

- How does Fabox handle uneven ground or elevation changes?

- Uneven or sloped sites are levelled using adjustable base systems or Layher platforms, enabling installation on grass, asphalt, or compacted ground without permanent foundations.

Systems Integration

Smart systems built in — lighting, climate, and technology made seamless.

- What lighting systems are available (LED, RGB, spotlights, strips)?

- Fabox supports LED downlights, RGB feature lighting, track systems, and exterior accents, all prewired and compliant with BS electrical standards.

- Does Fabox include HVAC? What options are available?

- Optional HVAC systems include wall-mounted split units or ducted systems providing heating, cooling, and ventilation for comfort in any climate.

- How is power distributed within the structure?

- Power is distributed through concealed electrical networks with prewired sockets, lighting, and RCD protection, offering plug-and-play interconnection between units.

- Can the ceiling support lighting, signage, or AV equipment?

- Yes, the roof frame is load-rated to support lighting, AV rigs, or suspended signage, with built-in fixing points for safe and flexible mounting.

- Are there weight limits for suspended or rooftop loads?

- Typical guidance: suspended point loads 0.5–1.0 kN per point with spreaders, or higher with a rigging plan. Rooftop uniform load for terraces typically designed up to 5.0 kN/m² for assembly or occupancy use.

- Can AV, audio, or LED wall systems be integrated seamlessly?

- Yes. Pre-planned cable routes, floor boxes, and concealed trunking are available. LED walls mount to pre-engineered fixing rails or internal frames, with load data and fixing details supplied in drawings.

- Are sanitary fixtures and plumbing options available?

- Fabox can be fitted with plumbing systems for toilets, sinks, and kitchens, designed for connection to mains, tanks, or temporary water systems.

Durability & Weather Resistance

All-season protection engineered for reliability and comfort.

- Is Fabox suitable for year-round outdoor use?

- Yes, Fabox is designed for all-season use, engineered to withstand rain, wind, snow, and temperature extremes while maintaining comfort and safety.

- What wind, rain, and snow load ratings does it meet?

- The structure complies with BS EN 1991 for wind and snow loads, with design wind speeds up to 25 m/s and snow loads up to 1.0 kN/m² depending on site conditions.

- Are materials fire-retardant, UV-resistant, and easy to maintain?

- Yes, the steel frame is non-combustible, panels are fire-rated to Euroclass B or better, and external coatings resist UV damage and corrosion for long-term durability.

- How does it perform in hot or humid climates?

- Its insulated construction, thermally broken glazing, and optional HVAC ensure comfort and moisture resistance in hot, cold, or humid climates worldwide.

- What certifications or standards does it comply with (engineering, fire, safety)?

- Fabox complies with Eurocode structural standards, including BS EN 1993 for steel design, BS EN 1090 for fabrication, and BS EN 13501 for fire safety.

- What materials or systems help with ventilation and temperature control?

- Insulated PIR composite panels, thermally broken glazing, trickle vents, and optional wall-mounted split HVAC or ducted systems. Intake or exhaust can be louvred. Dehumidification available where required.

Installation & Setup

Fast, simple, and engineered for precision on any site.

- How long does it take to install and dismantle a Fabox structure?

- A single Fabox can be installed in around one hour by a small team using a HIAB or crane, with multi-unit builds completed within a day.

- What equipment is needed for installation and removal (crane, forklift, or manual positioning)?

- Only standard event equipment is required—typically a HIAB or crane for lifting and a telehandler for component movement.

- Can Fabox be installed both indoors and outdoors?

- Yes, Fabox can be used both indoors and outdoors, offering flexibility for exhibitions, retail spaces, and open-air events.

- Does it require a foundation or can it stand directly on prepared ground?

- No permanent foundations are needed; Fabox installs directly on level ground or adjustable base plates.

- How is each unit anchored or stabilised (ground plates, ballast, tie-downs)?

- Each unit is self-weighted and stabilised through its steel base and bolted connections, requiring no additional ballast under normal conditions.

- Can it be installed on varied surfaces such as concrete, grass, sand, or asphalt?

- Yes, adjustable legs or Layher decks provide level installation on grass, sand, or asphalt surfaces without ground penetration.

- How does Fabox handle uneven or sloped terrain?

- Adjustable leg base plates or Layher platform levelling systems are used to achieve a true, level datum on grass, asphalt, compacted ground, or slabs. No permanent foundations needed.

- Does the floor system include adjustable feet or levelling mechanisms?

- Yes. Threaded base jacks and packers allow precise levelling and load distribution over prepared ground or temporary decks.

- What's the typical installation team size or manpower requirement?

- Single unit: 3–5 technicians plus crane/HIAB operator; multi-unit builds: 6–10 technicians. Times scale with access, ground conditions, and options.

- How is safety maintained during assembly and dismantling?

- Lift plans and RAMS, qualified slinger/signaller, LOLER-compliant lifting points, exclusion zones, edge protection for elevated work, and sign-off by the site lead. Toolbox talks at start of shift.

Transport, Storage & Efficiency

Compact to move, simple to store, and built for sustainable logistics.

- How are Fabox units packaged for transport?

- Steel stillages for frames, A-frames for glazing, protected crates for finishes and electrical, all itemised with pick lists. Exterior components are wrapped and banded for weather protection.

- How many units can fit on a single truck, and what type of vehicle is used?

- Up to 8 Fabox units per truck (load optimised design).

- What are the pallet or crate dimensions for shipping and storage?

- Typical stillage: approx 2.9 m × 1.2 m × 1.5 m; glazing A-frames: approx 3.0 m × 1.2 m × 0.4 m. Exact counts depend on options and quantity.

- How are units loaded, unloaded, and positioned on site (crane lift, forklift slots, etc.)?

- Lifting points for crane and forklift slots provided.

- Can Fabox units be stacked or nested for compact storage?

- Yes – designed for compact stacking.

- How much space (L × W × H or cubic metres) does one unit occupy when stored?

- Folded or packed footprint per unit typically 5.7 m × 2.9 m × 0.7–1.2 m (approximately 12–20 m³) depending on configuration and accessories.

- Are protective crates or covers included or optional?

- Weather covers and protective crates are included where needed for transport and can be specified as optional for long-term storage.

- How does the foldable transport system reduce logistics costs and emissions?

- Foldable design and 8-unit capacity per truck minimise hauls and fuel use.

- What are the average lead times from order to delivery?

- Rental: from 1–2 weeks subject to fleet availability and graphics. Purchase: typically 6–10 weeks for fabrication, coatings, and custom options. Lead times confirmed at order.

- How does Fabox compare to traditional container systems in efficiency and sustainability?

- Up to 8 Fabox units per truck versus approximately 2 traditional containers, reducing hauls, fuel use, and CO2. Foldable design and compact stacking lower storage volume and handling.

Branding & Customisation

Transform each Fabox into a fully branded, bespoke environment.

- Can Fabox be branded externally or internally?

- Yes, every surface of Fabox can be branded with wraps, printed panels, or digital media, creating complete brand immersion.

- What finishes and materials are available for walls and ceilings?

- Walls: insulated white panels, seamless glass, vinyl-wrapped or printed skins, acoustic panels, and timber or decorative cladding on fixing rails. Ceilings: insulated flat ceilings or stretched fabric systems with integrated lighting and service access.

- Can full graphic wraps or printed panels be applied?

- Yes. Full-coverage vinyl wraps, tension-fabric prints, and rigid printed panels are supported on both internal and external surfaces.

- Can additional cladding or decorative facades be fitted?

- Yes, Fabox includes dedicated fixing points for attaching custom cladding, facades, or architectural treatments.

- Are accessories like canopies, handrails, or awnings available?

- A full range of modular accessories is available, including canopies, terraces, and handrails designed to integrate seamlessly with the structure.

- Can signage, 3D logos, or LED screens be mounted externally?

- Yes, Fabox supports mounted signage and LED screens with pre-engineered connection points and load-tested fixing rails.

- Are 3D models or design files available for pre-visualisation?

- Yes. Revit, IFC, DWG, STEP, and SketchUp assets are available for coordination, with configured variants on request.

- Can interior finishes (vinyl, carpet, wood) be customised?

- Yes, interior finishes are fully customisable, with options for vinyl, carpet, wood, or branded materials to suit any event or retail environment.

- What materials or systems help with ventilation and temperature control?

- As above: insulated envelope, thermally broken glazing, trickle or louvre ventilation, and optional HVAC packages sized to occupancy and climate.

Safety & Compliance

Certified strength and safety you can rely on for every build.

- Does Fabox meet local and international building codes?

- Yes, Fabox is fully engineered to Eurocode and international standards, covering structural, load, and safety requirements for modular buildings.

- Are structural calculations or engineer-stamped drawings provided?

- Yes, all Fabox installations include full structural calculations and certified drawings prepared by qualified engineers.

- What fire safety features are included or recommended?

- Fabox includes a fire-rated steel structure and insulated panels with optional detectors and alarms, meeting UK Building Regulations Part B.

- Are there certifications for materials (fire, wind, load)?

- Each Fabox is supplied with a full certification pack including engineering calculations, material certificates, and fire and coating documentation.

- What emergency provisions can be integrated (exits, lighting, signage)?

- Illuminated exit signage, emergency lighting, fire detection and alarms, extinguishers, panic hardware on egress doors, and refuge or wayfinding signage to match local code and event CDM plans. Engineer-stamped drawings and calculation packs are provided for permitting.

Commercial & Support

Flexible purchase and rental options backed by expert support.

- Is Fabox available to rent, lease, or purchase?

- Fabox is primarily available for hire but can also be leased or purchased depending on project scale and duration.

- What's typically included in the package (transport, labour, insurance)?

- Packages include design, transport, installation, and insurance, providing a complete turnkey delivery to site.

- What warranty coverage is offered on the structure and components?

- The steel frame carries a 10-year warranty covering fabrication and weld integrity, with shorter terms for finishes and fixtures.

- Is technical or on-site support provided during setup?

- Yes, every Fabox installation is supported by trained technicians and engineers who oversee safe assembly and handover.

- What aftersales services or maintenance options are available?

- Maintenance, reconfiguration, and technical support are available throughout the lifespan of the installation, ensuring long-term reliability.